This post had been partially written months ago, just after Sandy Shores visited the 009 Society's 50th Anniversary Exhibition at Statfold Barn - apologies for the delay, and that things are out-of-date!

All of a sudden, the forthcoming 50th anniverary celebration exhibition of the 009 Society was bearing down on me! I feel very privileged that Sandy Shores was invited all the way to Statfold Barn in Tamworth for this exhibition - all despite me not being part of the 009 Society at the time (duly rectified in time for the show!). It was thus time to set the layout up in the studio and see what needed fixing, modifying, or maybe even rebuilding...

Fiddle yard

- Not all the rails seemed to line up perfectly - it seems like the approach track had twisted/raised slightly (or was never perfectly installed in the first place).

- There had never been a need to turn the turnplate more than a few degrees - since;

- the locos derail if going bunker first towards the fiddle yard from the loco shed headshunt (so I don't ever turn them)

- there is no run-around loop, so there's also no need to turn entire trains

- the three sidings shown in the photo of the fiddle yard below never get used despite being wired up - not even to hold stock on!

- There is very limited clearance between the three tracks on the turnplate.

- There is limited siding capacity.

Above: A montage showing the tight clearance on the current turnplate, followed underneath by a potential traverser with a wider track spacing. Note: whilst I've shown a 5 track traverser, in reality, a 4 track traverser would fit the space better - otherwise the control panel would not fit without overhanging the baseboard edge.

And so off I went to knock up the design on my computer using Sketchup. After a bit of trial and error, and numerous versions, I settled on this:

In the 3D render below, I've superimposed the old turnplate fiddle yard with the new traverser. The latter is only about 43mm longer than the original (as it turns out, it's about half of that shown in the 3D model), so will not result in an increased space required to operate the layout (as I always added an extra two feet on exhibition manager handouts in case access was required past the end of the layout).

Above: Superimposing the old with the new fiddle yard shows only a marginal increase in board length, but with greater storage capacity. Another handy design feature is that the traverser tracks are exactly the same length as the headshunt on the layout - so I will never have to guess the capacity of both ever again!

A further happy bonus of this new fiddle yard will be a longer approach track, which should mean that I will be able to add, if desired, even more 'fake scenery' onto the fiddle yard to further disguise the transition between scenic, and non-scenic areas of the layout. It should also stop hands being so visible beyond the scenic section!

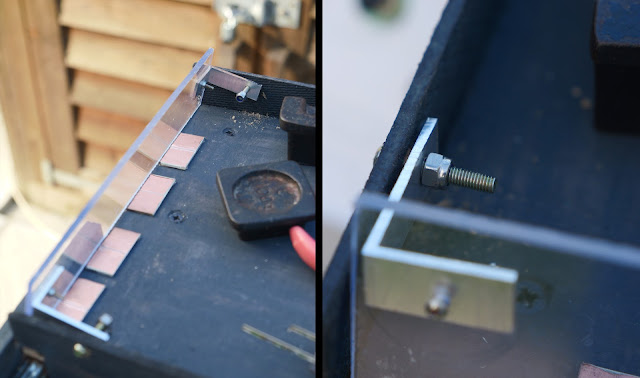

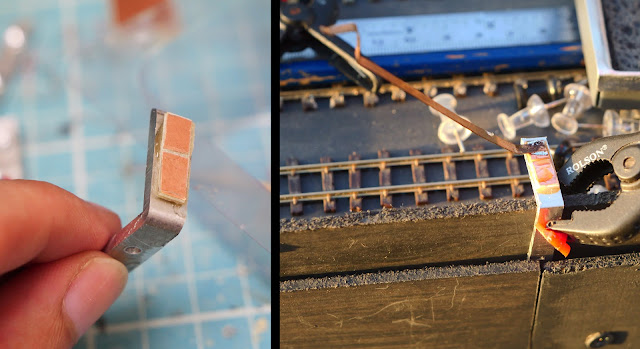

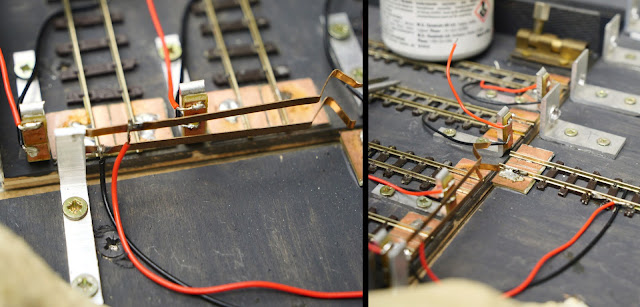

Above: A close-up of the sprung wipers and copper-clad board electrical contacts. A simple, but effective method of carrying electricity from the approach track and onto the fiddle yard. Having it above-board means maintenance is a doddle.

Above: Happy that everything works nicely, the fascias can now be fitted to the sides of the traverser. Note the bits of white plastic (cable tie bases) temporarily holding this piece above the bottom of the 'well' whilst I screw it into place - this will create a gap to prevent the fascia potentially scraping the well.

Above: Two types of brackets will be needed: thin ones beside each track, and wider ones that will have a hole cut in each. The latter is required for the barrel bolt, which will help create the traverser indexing, to slide in. To mark the correct height of the hole, the end of the barrel bolt is coated in felt tip pen. The bolt is then slid across until it touches the bracket - thus marking the centre point of the required hole.

Above: The aluminium angle will obviously need holes drilled for the barrel bolt (that's another story entirely as it took ages to find the perfect sized drill bit!), but to make sure there is minimal propensity for the brackets to move and thus ruin the traverser indexing, I decided to screw them down. This of course means that holes are also needed to be drilled for that. Two screws of course minimising the tendency for the brackets to twist. To drill the holes successfully, two things are key; firstly, using a punch and hammer to dent the aluminium to guide the drill bit, and secondly, to use a pillar drill (thus ensuring the hole is perfectly vertical. Note that a vice is used for safety reasons, and also as a further way to make sure that the drill bit doesn't wander.

Above: Before the new plywood top for the non-traverser section of the fiddleyard is secured, the approach track position is marked on top, two small holes are drilled either side, and a black and a red wire is fed through; which will later power the entire fiddle yard. Something to note is that the screws that secure the plywood top to the softwood supports underneath had their holes countersunk to ensure the screw heads sit flush, or below the top surface. The whole fiddle yard was then painted with the same dark grey paint that the fascias and layout trolley were when first built. Note the messy wiring of the control panel - something to fix another day!

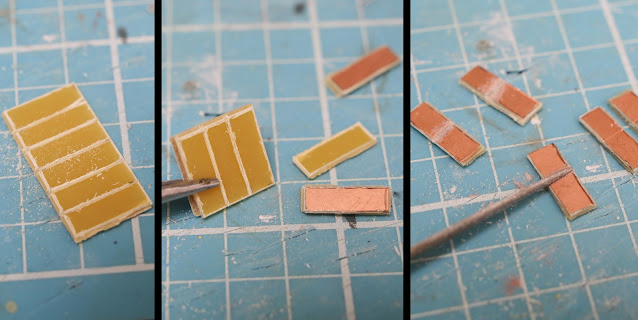

Above: Now that all the copper clad panels have been cut, gapped, and epoxied into their correct positions, the track can be soldered to them. As the approach track had to be relayed now that it needed to be longer, a single piece of track was used for this, and the first traverser track. This meant that I could be 100% sure that at least one track would align perfectly! These rails, once fully soldered, could then be cut with a cutting disc on a Dremel. The rest of the tracks were mainly aligned by eye, though I did put a straight edge to each side of the rails to check the alignment was correct. Something to note is that the barrel bolt on the traverser was engaged with the relevant aluminium bracket whilst soldering the track in place - the brackets had previously been secured to the non-moving part of the fiddle yard at regular intervals, at the same time as the copper clad panels were glued.

The narrow aluminium angles (which the sprung wipers will strike against for electrical power) were then screwed to the traverser; making sure to keep them all at the same distance from the adjacent rail to the left. That meant everything aligned as it should, and that the wipers will always contact the correct angle to provide power to the relevant track.

Above: A final view of the wiring set and general fiddle yard set up. The inset photo shows my mistake not double-checking which way around the wires should be; thus I had to reverse the wires after everything shorted upon powering the layout! At least it wasn't soldered, just screwed into the connector. Ignore the screw poking through...!

Above: A final overview of the rebuilt fiddle yard. Note the wooden knob that provides a safe way to pull and push on the traverser. Someone asked me why it was there, when the 'handle' of the barrel bolt could be used instead, resulting in only one hand needing to be used to lock it in place. The answer is that, for some reason, the traverser sticks if pushed from that end! This photo also shows why the perspex drop-down shield is necessary.

Minor additions and repairs

As seemingly happens after every exhibition, the headshunt trestle is the first item on the agenda in terms of needing repair. Noted previously, the handrails are incredibly delicate, and it only takes one second of lapsed concentration when maneouvring the layout to get it snagged on something and demolish the handrails and even the buffer stop. Fortunately, I kept the broken section of handrail safe in the box where the buildings are placed for transportation - so it was a simple case of gluing it back on with a steady hand.

Elsewhere, the lighthouse railings are another delicate feature. Unfortunately, these often take a battering, too! Mostly because I have no way of transporting it safely, so it often sits on the front seat of the car on the way to/from exhibitions! I was doing well keeping it safe on its last outing until I got home - upon releasing the handbrake to reverse the car into my drive, I wasn't looking where I was putting my hand, and clipped the lighthouse railing; instantly breaking it into 3 sections... whoops! A bit of bending of the wire with some fine nosed pliers and some epoxy later, and, whilst not perfect, it is at least more-or-less back in place... until the next time it isn't!

(Post-show report: Coming back to finish this blog entry after the show, I can attest that it certainly wasn't long before it got damaged again - my Dad dropped the lighthouse because we had wedged it against a bunch of coats and a closed car door in order to 'keep it safe'! Needless to say, he forgot the warning about 'NEVER open this door' when it came to unloading the car at the holiday cottage. He was mortified, but the damage wasn't too bad surprisingly, and I could fix it the night before the show. To be fair, what a stupid place to put the most delicate object!)

Elsewhere, it occurred to me that it would be a good idea to glue some things together that were previously just loosely 'assembled' whenever the layout was set up - such as the roof of the lighthouse lantern room, and the ladder to the water tower. This also gave me a great excuse to further embellish and detail both of these. Let's start with the water tower:

By this point, it was time to pack everything up and head to the holiday cottage (so photos from now on won't be as good quality as the lighting was less-than-ideal there)...

Above: Having brought all my paints, glues, paper towel, and even a small jamjar of water so that I could use its lid as a paint palette, I got to work finishing off the water tower by adding and painting the new detailing. As well as the outlet pipe/hose and the 'cistern' mechanism, I also added a thin inlet pipe so that it looked as though there was a feasible way that water could enter the tank. Oh, and I just realised that I never showed the tiny handrail I added from finely chopped lollipop stick. You can just about see it on the top of the 'landing' above the ladder if you look hard enough!

Well, that's everything for this blog entry. Coming up next time, we'll discuss another fairly big change to the layout...

.JPG)

.JPG)

COMBO.jpg)

COMBO.jpg)

COMBO.jpg)

COMBO.jpg)

COMBO.jpg)

COMBO.jpg)

.jpg)

.jpg)

sm.jpg)

.JPG)

.JPG)

.JPG)

Comments

Post a Comment